Introduction

In the world of LED showcase lighting, beauty and brilliance catch attention, but longevity earns trust. Whether it’s jewelry display showcase lighting, museum exhibits, or retail installations, how well your lights handle heat decides how long they’ll perform at their best.

At LightrixTech, we design lighting systems that look elegant but are engineered for endurance. From magnetic track lights and mini LED pole lighting to rotating LED bars, each product undergoes meticulous thermal testing. Behind every beam of light lies one invisible hero—thermal management.

Why Is Heat a Problem in LED Showcase Lighting?

Heat is common in lighting design. It is a big, often overlooked problem. Old bulbs release heat quite easily. LEDs trap heat inside their solid parts. When heat builds up, trouble starts. Colors fade, brightness drops, and the whole system can fail over time too.

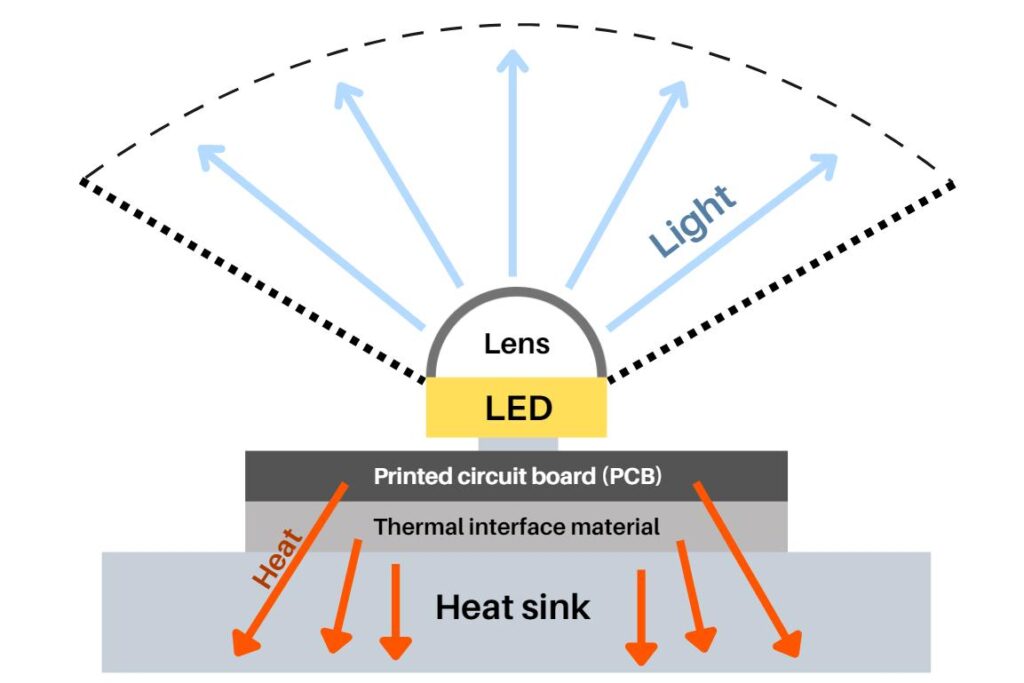

Each LED has a junction. This spot is where electricity becomes light. When the junction temperature gets too high, LEDs dim faster. They also shift in color (lumen depreciation) as time passes over the years. The driver circuit powers the LED. It overheats and shortens its life.

Table 1. Common Effects of Poor Thermal Management in LEDs

| Issue | Description | Impact on Showcase Lighting |

| Lumen Depreciation | Gradual decrease in light output | Dull, uneven illumination in displays |

| Color Shift | Change in color temperature over time | Alters jewelry tones and artwork hues |

| Driver Stress | Overheating electronic components | Causes flicker or sudden failure |

| Reduced Lifespan | Early burnout of LEDs and drivers | Higher maintenance and replacement cost |

In display environments—especially jewelry showcases—color accuracy is everything. A small shift from 4000K to 4200K can distort the sparkle of diamonds or make gold appear duller. That’s why heat isn’t just an engineering issue; it’s a visual one.

What Does Good Thermal Design Look Like in Showcase Lighting?

Thermal management isn’t about adding one extra part—it’s an entire system of design choices working together. Every magnetic showcase track lighting or mini showcase track lighting unit at LightrixTech is built with this in mind.

Table 2. Key Thermal Design Elements and Their Functions

| Design Element | Purpose / Benefit | Where You’ll Find It |

| Aluminum Housing | Conducts heat efficiently | Magnetic track lights, LED bars |

| Heat Sinks / Fins | Expands cooling surface | Mini pole spotlights |

| Thermal Pads / MCPCB | Transfers heat from chip | Inside LED modules |

| Airflow Spacing | Prevents heat buildup | Cabinet-mounted lights |

| Driver Derating | Reduces power stress | LED drivers in jewelry cases |

| Thermal Testing | Ensures reliability | LightrixTech product validation labs |

All of this happens behind the scenes. To the eye, you see slim, elegant luminaires. Underneath, however, precision heat control ensures every sparkle remains sharp for years.

Why Does Thermal Design Matter More in Display Environments?

Lighting for display cabinets—especially jewelry showcase lighting—faces challenges general room lighting never encounters.

- Tight Enclosures

Display cases are compact, often sealed to keep dust away. That means less airflow and higher ambient temperatures inside the cabinet.

- Long Operating Hours

Many museum or retail displays stay lit for 10–14 hours a day. Without good heat dissipation, even small fixtures can reach unsafe internal temperatures.

- Color-Sensitive Applications

In art galleries or luxury stores, consistency is key. If one spotlight shifts color slightly, the entire display harmony is lost.

- Sensitive Objects

Too much heat can damage delicate items. Some of these items include paintings, fabrics, gemstones. Keep the light cool to the touch. It protects performance and keeps all people safe..

Because of these constraints, thermal management isn’t optional—it’s essential. At LightrixTech, we treat heat as a design input from day one, not an afterthought. Our mini magnetic showcase track lighting and compact fixtures are proof that small size doesn’t mean compromise on heat control.

How Does LightrixTech Engineer Thermal Stability Into Its Lights?

Every LightrixTech product undergoes multi-stage thermal optimization. This process combines electrical, mechanical, and environmental tests. It simulates real-world conditions.

Here’s how it works behind the curtain:

- Material Selection – We use high-conductivity aluminum extrusions for body design. Aluminum not only looks sleek but conducts heat far better than plastic housings.

- Smart Power Design – Partnering with leading driver and chip suppliers, we adjust current and voltage to minimize excess heat at the source.

- Compact Custom Paths – When space is limited, such as in ultra-thin magnetic track lighting, we create dedicated heat-escape routes through internal channels and contact points.

- Field Simulation – Prototype testing includes closed-cabinet scenarios to measure how heat behaves during 12+ hours of continuous use.

- Performance Validation – Our engineers validate that junction temperatures stay below manufacturer limits to preserve luminous efficacy and chromatic stability.

Through this approach, our lighting products maintain stable brightness and color consistency even after thousands of operating hours.

What Are Real-World Applications of LightrixTech’s Thermal Practices?

Here are a few ways we implement our thermal expertise in actual product lines:

- Magnetic Track Light Systems: Our Magnetic Track Lights use extruded aluminum channels. They act as quiet, passive heat sinks that release heat.

- Mini Showcase Track Lighting: Compact fixtures keep junction temperatures low. Housings stay small, yet effective.

- LED Bars for Displays: Feature internal copper cores for fast thermal conduction and stable output.

- Custom Configurations: For irregular cabinet designs, we design adaptive thermal routes to maintain performance.

How Can Clients Evaluate a Supplier’s Thermal Design Knowledge?

When buying lights, check heat control. In high-value retail or museums, ensure the maker treats heat management with care and seriousness.

Even high-lumen LEDs are not immune. According to industry studies, every 10°C increase in junction temperature can reduce LED lifetime by 30–50%.

Here’s how to start that conversation:

Table 3. Essential Thermal Management Questions for Lighting Projects

| Question to Ask | Why It Matters | Ideal Answer / Expectation |

| What is the maximum LED junction temperature? | Determines long-term stability | Below 85°C under continuous use |

| What housing material do you use? | Affects heat transfer efficiency | Aluminum alloy preferred |

| How was the product tested? | Validates real-world performance | Tested in enclosed cabinet conditions |

| How do you derate the driver? | Prevents overheating and failure | Operates below max rated power |

| What’s the expected lumen depreciation curve? | Shows consistency over time | L70 > 50,000 hours |

If a vendor focuses only on brightness or aesthetics without discussing thermal limits, it’s a red flag. A product that’s “bright now” but degrades quickly costs more in maintenance and replacements later.

For long-term ROI, thermal transparency is non-negotiable.

What’s the Future of Thermal Management in Showcase Lighting?

LEDs get smaller and stronger. So smart heat control becomes even more vital today. New tech is here now for top-tier lights. Think graphene heat sinks, liquid metal cooling, and AI thermal sensors.

These technologies are still evolving. LightrixTech stays practical and reliable, using proven materials and careful power management that work in real-world settings today.

The next generation of magnetic track lighting systems from LightrixTech will feature improved conduction pathways and optional smart temperature sensors that automatically regulate brightness under extreme ambient heat.

These developments aim to create a future where your lighting stays just as stunning in year five as it did on day one.

Conclusion

In display lighting, it’s not enough for a fixture to look good out of the box. Real excellence shows after thousands of hours of operation. That’s what thermal management guarantees—sustained brilliance, color accuracy, and reliability.

At LightrixTech, every product—whether a magnetic track light, mini showcase track lighting, or custom LED jewelry lighting system—is engineered from the inside out to control heat effectively.

External Links:

- https://www.nisshinbo-microdevices.co.jp/en/faq/040.html

- https://en.wikipedia.org/wiki/Lumen_maintenance

- https://www.agcled.com/blog/temperature-fluctuations-led-lights-challenges-impacts-solutions.html#:~:text=Industry%20studies%20suggest%20that%20for%20every%2010%C2%B0C,temperature%2C%20LED%20lifespan%20may%20decrease%20by%2030%2D50%25.

- https://www.sciencedirect.com/science/article/pii/S0921452624003168