Introduction

When you think about LED lighting, what comes to mind?

Chips. Drivers. Brightness.

Here’s the catch. None of these can truly work well without the right housing.

Your LED’s housing matters. It could be made from aluminum or plastic. It affects how long it lasts and its heat-handling ability. It also affects how it looks in a jewelry display.

So which one should you trust for long-term LED performance? Let’s explore in detail.

What Role Does Housing Play in LED Lighting?

LED housing is more than a shell. It’s the protector, the manager, and the stylist.

Why does it matter?

- Heat dissipation: It keeps the LED chip cool. It also extends its life.

- Structural protection: It protects electronics from elements. These includes dust, moisture, impacts.

- Aesthetic integration: Helps lighting blend in with jewelry showcase lighting. Works in any architectural setup too.

Think of the housing as the armor of your LED. If the armor is weak, the light won’t survive the battlefield.

But there’s more: housing also influences installation and maintenance. Aluminum housings fit magnetic track light systems better. Their strength and stability keep the system firm, while plastic housings can flex or deform during repeated installations.

In high-end spaces like museums or galleries, stable housing matters. It keeps lighting angles precise and consistent for years.

In addition, housing affects customer experience. A cracked or yellowed fixture in a luxury jewelry store can break the atmosphere of elegance. That’s why lighting designers treat housing as a critical factor, not an afterthought.

| Housing Function | Why It Matters in LED Lighting |

| Heat Dissipation | Prevents LEDs from overheating, keeps brightness stable |

| Structural Protection | Shields chips and drivers from dust, UV, and impact |

| Aesthetic Integration | Provides the sleek finish needed in retail and luxury displays |

| Installation Reliability | Ensures consistent fit with systems like magnetic track lighting |

At LightrixTech, our LED showcase lighting is engineered with precision housings, ensuring durability without compromising design.

Why Is Aluminum Housing Considered Premium?

If you’ve ever seen a luxury magnetic showcase track lighting system, chances are the housing was aluminum.

| Advantage of Aluminum | Real-World Benefit |

| High thermal conductivity | LEDs stay cool → longer lifespan |

| UV & impact resistance | Suitable for museums and high-end retail |

| Elegant finishes | Ideal for jewelry showcase lighting |

| Sustainable & recyclable | Supports green building practices |

Downsides? Aluminum costs more and is slightly heavier. But in long-term use, the investment pays for itself.

Is Plastic Housing Worth Considering?

Yes. But only in the right context.

Plastic is everywhere in mini showcase track lighting because it’s:

- Lightweight – Easy to move and install.

- Budget-Friendly – Lower raw material and production costs.

- Flexible in Design – Injection molding allows for creative shapes.

| Advantage of Plastic | Real-World Benefit |

| Lightweight | Perfect for suspended lighting fixtures |

| Cost-efficient | Cuts down project expenses |

| Moldable | Enables creative fixture designs |

But beware:

- Plastic has poor thermal conductivity (~0.2 W/mK).

- It may yellow or crack under UV light.

- Heat stress leads to faster degradation.

That’s why high-end LED jewelry lighting almost never relies solely on plastic housing.

Still, plastic can be practical. For example, traveling exhibition booths or mini LED pole lighting displays at trade fairs often use plastic because the fixtures only need to last a few months. Here, saving money matters more than long life. Low weight matters more.

Plastic also gives makers freedom to design complex, decorative shapes. This can be useful for artistic installations too. For critical retail and gallery lighting, plastic falls short. Aluminum keeps up, and excels overall.

Why Is Heat Dissipation So Important for LEDs?

Here’s a simple truth: Heat kills LEDs.

For every 10°C rise in junction temperature, LED life can shrink by 40%.

- Aluminum housing actively channels heat away.

- Plastic housing traps it—unless you add extra heat sinks.

| Material | Heat Conductivity (W/mK) | LED Lifespan Impact |

| Aluminum | ~205 | Maintains brightness for years |

| Plastic | ~0.2 | Higher junction temp → faster decay |

That’s why serious installations—like magnetic track lighting in galleries—nearly always choose aluminum.

When Should You Choose Aluminum Housing?

Pick aluminum when:

- Lighting runs long hours daily (museums, jewelry shops, retail).

- High-power LEDs are needed.

- Premium finish is a must.

- Long-term ROI matters more than upfront cost.

For example, a magnetic track light in a jewelry store needs consistent brightness and zero warping. Aluminum guarantees both.

When Does Plastic Housing Make Sense?

Plastic is useful when:

- Budget is tight (short-term exhibitions, pop-up shops).

- Weight is critical (portable display kits).

- Fixtures are decorative, not high-power.

A temporary trade fair using mini LED pole lighting can cut costs with plastic housings. But for permanent store lighting? Aluminum wins.

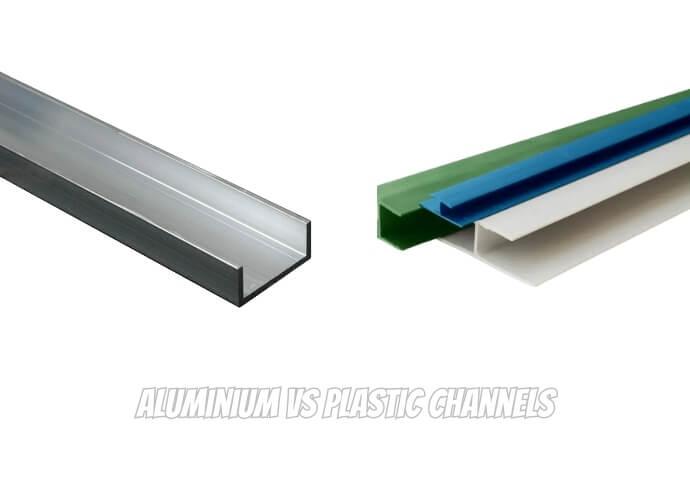

How Do Aluminum and Plastic Compare Side by Side?

Look up close. Aluminum and plastic do different jobs. Very different needs indeed. Aluminum is made to last. Plastic is best for temporary or light use.

Aluminum housings lead in premium retail. But plastic housings can fade or discolor. That creates uneven tones and can ruin the display. Aluminum, by contrast, keeps the light uniform and stable.

Here’s a quick reference table:

| Feature | Aluminum Housing | Plastic Housing |

| Heat Dissipation | Excellent (205 W/mK) | Poor (0.2 W/mK) |

| Durability | UV & impact resistant | Prone to yellowing, cracking |

| Weight | Slightly heavier | Very lightweight |

| Cost | Higher upfront | Lower upfront |

| Lifespan | 50,000+ hours with ease | Shorter, unless reinforced |

| Applications | Museums, jewelry, premium retail | Exhibitions, pop-ups, accents |

This side-by-side view shows why aluminum dominates in magnetic showcase track pole lighting—its heat stability and durability protect your investment. Plastic can still win in cost-sensitive projects, but over time, replacements eat into the initial savings.

How Does Housing Affect Showcase Lighting Design?

A beautiful display is only as strong as its lighting.

- In jewelry display showcase lighting, aluminum ensures no flicker or dimming over time.

- In mini magnetic showcase track lighting, plastic can work for accents, but aluminum makes sure diamonds sparkle consistently under heat.

So, Which Housing Is Best for Long-Term LED Performance?

Both materials have roles. But let’s be clear:

- Aluminum = long-term performance.

- Plastic = short-term savings.

If you’re designing magnetic showcase track pole lighting for luxury retail, aluminum isn’t just better—it’s essential.

Conclusion

Aluminum housing wins. It’s best for long-term LED performance overall.

It protects your investment. You get great cooling, long life, and a premium look. Plastic may save money upfront, but it compromises durability.

At LightrixTech, we design LED showcase lighting with aluminum housings, ensuring brilliance and stability in demanding environments.

Looking to upgrade your displays?

Explore our magnetic track lighting solutions today and bring lasting elegance to your showcases.

External Links: