Introduction

The housing color in showcase lighting is more than decoration. It shows your brand, sets the mood, and hides distractions. Using LED showcase or magnetic track lighting, the right finish gives cabinets and open shelves a flawless look. The two top methods for coloring aluminum housings: anodizing and powder coating. Each has its own benefits and trade-offs.

What Is Anodizing And How Does It Work?

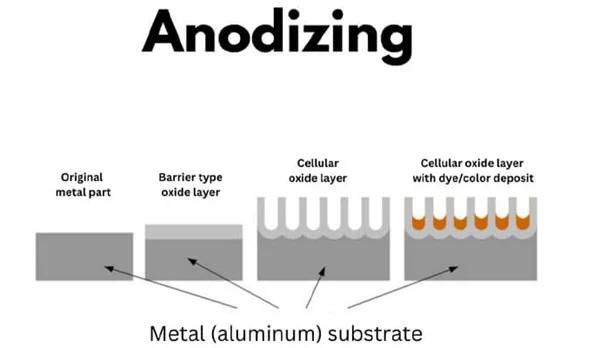

Before diving into anodizing, it helps to understand its purpose in lighting. Aluminum is lightweight and easy to mold. That is why it is common in Mini LED pole lighting and other display setups. But without surface protection, it can wear down or corrode. Anodizing solves this.

This process uses electricity and chemicals. It grows a protective layer from the aluminum itself. Unlike paint, it doesn’t coat the surface—it transforms it. This finish is actually part of the metal. It is tough enough for long-term use in professional displays.

Have you ever wondered why fancy jewelry displays shine so smoothly? They use a thin metal coating that stays bright for years. That’s anodizing in action. Anodizing is a way to make aluminum tougher and resist rust. It works by making the aluminum’s oxide layer thicker.

It’s not a paint—it becomes part of the metal. This model suits fancy stores and displays with magnetic pole track lighting. It gives a stylish look and long life.

- Technical takeaway: The thickness adds durability and scratch resistance.

- Why it matters: The finish doesn’t flake or chip, so it keeps your display looking fresh.

Pros Table:

| Benefit | Why it matters |

| Durable & scratch‑resistant | Creates a permanent, tough surface |

| Premium metallic gloss | Offers deep, rich finishes |

| UV stable | Color resists fading in sunlight |

| Eco‑friendly | Low VOC emissions, recyclable process |

Cons Table:

| Limitation | Impact on choice |

| Higher cost | Requires specialized equipment and labor |

| Limited palette | Mostly metallic tones only |

| Thin layer | Can scratch (not chip) under impact |

What Makes Powder Coating A Solid Alternative?

While anodizing bonds with the metal, powder coating covers it entirely. If you’ve ever seen a colorful LED showcase lighting unit in a retail store, it’s likely powder-coated. This method offers more design freedom.

Powder coating uses a fine dry powder sprayed onto metal. Then it’s baked at high temperature until it melts and bonds into a smooth, protective layer. It’s popular because it can handle curves, edges, and unique textures without peeling.

Looking to add bold color, glossy finishes, or textured effects to your Mini magnetic showcase track lighting? Powder coating may be your best bet.

Powder coating is a dry paint that sticks to a surface using an electric charge. Then it bakes on to form a tough, protective layer. It creates a hard, protective coat on the aluminum. You can use bright designs and still keep costs lower on medium-sized projects.

- Why it matters: Powder coating offers creative freedom with color and texture.

- Real-world use: Many retail stores use this method for their magnetic track light setups to reflect brand identity.

Pros Table:

| Benefit | Advantage |

| Vast color choices | Hundreds of colors and finishes |

| Robust protection | Thick layers guard against chips and corrosion |

| Cost-effective for mid-runs | Lower setup cost compared to anodizing |

Cons Table:

| Downside | What you should know |

| Chipping risk | Damage leads to flaking—hard to repair |

| UV fade possible | Some pigments discolor in sunlight |

| Thicker coat | May affect tight mechanical fits |

Which Finish Fits Your Display Needs Best?

Your choice of finish impacts everything—from how your brand is perceived to how often your lighting needs maintenance. In magnetic track lighting, where precision is key, even a small variation in layer thickness can cause assembly issues.

If you value durability and sleek metallic style, anodizing might be better. If your project uses bold color, you must match brand hues exactly. Powder coating is often truly the smarter option.

Picking anodizing or powder coating is like choosing between apples and oranges. They each have their own job. Anodizing is the best way to make metal strong and last a long time. Powder coating is the best way to get bright, fun colors.

This breakdown will help you decide which suits your LED showcase lighting setup best:

| Criteria | Anodizing | Powder Coating |

| Durability | Outstanding scratch & corrosion | High impact and chemical resistance |

| Color Range | Metallic tones only | Huge variety: matte, gloss, textured |

| Aesthetic Style | Sleek, high-end metallic | Match brand colors with texture options |

| Cost (per unit) | High setup costs | Affordable for mid-sized runs |

| Repair/Maintenance | Permanent, little repair needed | Needs full recoating if damaged |

| UV Resistance | Excellent | Generally good, fade risk over time |

| Layer Thickness | Thin and dimensionally stable | Thick—may affect fit |

Where Should Each Finish Be Used?

No two lighting environments are the same. Display needs in a sun-drenched boutique differ from those in a quiet, dim-lit museum. Selecting a finish isn’t just about looks—it’s about context.

Use anodizing where long-term durability and metallic aesthetic matter most. Choose powder coating when you want to create eye-catching displays in bright, changing retail settings.

Anodizing is perfect for:

- Museums, galleries, and luxury jewelry showcases

- Long-term installations with minimal touch

- Outdoor or sunlit displays needing high UV resistance

Powder coating works best in:

- Retail stores and pop-up exhibitions

- Displays using Mini LED pole lighting in custom colors

- Brand-driven setups with frequent layout changes

How Does LightrixTech Guide Your Finish Selection?

Choosing between finishes is easier when you have expert support. At LightrixTech, we don’t just offer lighting—we help you make smart visual decisions.

Finishing is part of our product DNA. Maybe you’re adding lights to a jewelry display. Or you’re rebranding a store chain. We blend style and strength to meet your needs.

- Need a sleek, metallic look? We offer custom anodized finishes.

- Want colors that pop? Our powder coating options span matte, gloss, and textured finishes.

- Not sure what you need? We provide samples to test with your cabinet materials.

- Our team helps you match your lights with your Jewelry display showcase lighting setup perfectly.

Explore our product lineup to visualize your design goals in action.

What Should You Ask Before Choosing?

Asking the right questions helps avoid expensive mistakes. Before finalizing your housing finish, think about:

- Will it face sunlight daily? → Pick anodizing.

- Do you need custom brand colors? → Powder coating is your friend.

- Is precision fit important? → Anodizing’s thinness works best.

- Are you on a budget? → Powder coating is more scalable.

- Need long-term performance? → Anodizing lasts decades with minimal change.

These aren’t just preferences—they shape the success and lifespan of your lighting installation.

How Do You Ensure Professional Results?

Even the best finishes can fall short if applied poorly. Professional results depend on how well you prepare. Always prototype first—use real materials, check coating thickness, and verify fit.

At LightrixTech, we help prevent common mistakes by offering sample testing, expert consultations, and end-to-end design collaboration.

- Sample first: Don’t guess. Request real samples.

- Measure coating thickness: Know your tolerance levels.

- Think ahead: Coating processes add production time.

- Consult experts: Our LightrixTech team can assist with technical advice to avoid fit or fading issues.

Conclusion

Customization of display light housing color—via anodizing or powder coating—is a strategic decision. You must balance durability, aesthetics, color customization, and budgets. With anodizing, choose premium metallic, long-lasting finishes. For brand-specific, textured color needs in magnetic showcase track lighting, select powder coating. Your decision should prioritize your brand’s visual identity and the environment in which your displays will live.

External Links: